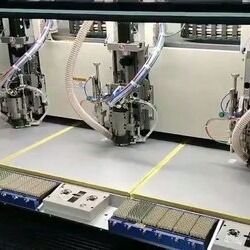

Bancada de Painel de Alumínio Honeycomb para Oficina de PCB de Alta Limpeza

Descrição do Produto:

A estrutura hexagonal do núcleo de favo de mel de alumínio pode dispersar forças, com um peso de apenas 30% -50% das bancadas de metal sólido tradicionais sob a mesma capacidade de carga, tornando-o fácil de transportar e instalar equipamentos. Baixo coeficiente de expansão térmica, não deforma facilmente nos processos de alta e baixa temperatura da produção de PCB (como soldagem e secagem), pode garantir a precisão da mesa e evitar o deslocamento do processamento da placa de PCB.

Dimensões recomendadas para bancadas de painel de alumínio honeycomb PCB

| Categoria |

Tamanho (mm) |

Cenários de aplicação |

Vantagens |

| Tamanho padrão |

1220*2440 |

Bancadas pequenas de PCB, plataforma de teste |

Disponível em estoque, baixo custo |

| Tamanho personalizado regular |

1500*6000 |

Bancadas de linha de produção de PCB de tamanho médio |

Alta planicidade e melhor adaptabilidade de tamanho |

| Tamanho grande personalizado |

2000*12000 |

Bancadas de linha de produção de PCB automatizadas em larga escala |

Reduz a emenda e garante a integridade da bancada |

| Espessura comum |

25, 30, 40 |

Diferentes requisitos de pesagem de bancadas de PCB |

Quanto maior a espessura, maior a capacidade de carga |

| Material do painel |

Al3003, Al5052 |

Bancadas de PCB de alta limpeza |

Resistente a ácidos e álcalis, não enferruja facilmente |

| Material do núcleo |

Tamanho da célula 50~100mm, espessura da folha 0,08~0,15mm |

Bancadas leves de alta qualidade |

Reduzindo a capacidade de carga do equipamento |

Características das bancadas de painel de alumínio honeycomb PCB:

Leve e Alta Resistência: As bancadas de painel de alumínio honeycomb PCB são conhecidas por sua natureza leve e alta relação resistência-peso. O design do núcleo em favo de mel, intercalado entre as folhas de alumínio, cria uma estrutura composta leve, mas rígida, oferecendo excelente resistência e capacidades de suporte de carga.

Integridade Estrutural e Estabilidade: bancadas de painel de alumínio honeycomb PCB fornecem integridade estrutural e estabilidade superiores. A estrutura do núcleo em favo de mel distribui as cargas uniformemente, aprimorando a capacidade do painel de resistir a forças de compressão, cisalhamento e flexão. Essa propriedade garante desempenho e durabilidade a longo prazo.

Propriedades de Isolamento Térmico: bancadas de painel de alumínio honeycomb PCB oferecem isolamento térmico eficaz. A estrutura em favo de mel e as células preenchidas com ar dentro dos painéis minimizam a transferência de calor, regulando a temperatura e melhorando a eficiência energética em várias aplicações.

Aplicações de bancadas de painel de alumínio honeycomb PCB:

Montagem de precisão (como linha de produção SMT): planicidade extremamente alta, excelente estabilidade dimensional (expansão e contração térmica), função integrada de adsorção a vácuo para fixar placas de circuito.

Testes e inspeção funcionais (como FCT, ICT): excelente resistência à vibração, boa blindagem eletromagnética (opcional), resistente e durável.

Montagem e manutenção universal: boa rigidez, resistência ao desgaste, fácil limpeza, antiestático, econômico.

Embalagem e Envio:

bancadas de painel de alumínio honeycomb PCB são enviadas em embalagens protetoras para garantir que cheguem ao seu destino em perfeitas condições. Os painéis são fixados em uma caixa de papelão e cercados por espuma para evitar qualquer dano devido a impactos. A caixa é então fixada com fita adesiva forte para evitar qualquer abertura. Além disso, a caixa é marcada com “Frágil” para alertar os manipuladores sobre o produto interno. O pacote é então rotulado com o endereço do destinatário e é enviado usando um método de envio apropriado.

Perguntas frequentes:

- P: O que são bancadas de painel de alumínio honeycomb PCB?

R: Os painéis de favo de mel de alumínio são painéis compostos leves feitos de núcleo de favo de mel de alumínio intercalado entre duas peles de liga de alumínio, que podem ser aplicados à bancada de trabalho de PCB.

- P: Quais são os benefícios das bancadas de painel de alumínio honeycomb PCB?

R: A estrutura hexagonal do núcleo em favo de mel pode dispersar forças e, sob a mesma capacidade de carga, o peso da bancada de placa de favo de mel de alumínio PCB é de apenas 30% a 50% daquele das bancadas de metal sólido tradicionais, tornando-o fácil de manusear e instalar equipamentos. Não deforma facilmente durante o processamento em alta temperatura, pode garantir a precisão da mesa e evitar o deslocamento do processamento da placa de PCB.

- P: Podemos aceitar a personalização de tamanho?

R: Sim, nosso tamanho regular é 1220 * 2440 e o tamanho grande é 2000 * 12000mm.

Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!  Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!